What makes us experts? We’ve been manufacturing bulk storage tanks for over 30 years. Our AdBlue tanks are used by hundreds of private fleet operators and in public forecourts throughout Europe including as an exclusive tank range for one of Europe’s leading AdBlue producers and suppliers. In this guide, we’ve collated vital information you need to know when considering the purchase of a bulk AdBlue® storage tank.

What is AdBlue® and what is it used for?

AdBlue® is a solution of high-purity urea (32.5%) and deionised water (67.5%). In a process called Selective Catalytic Reduction (SCR) AdBlue® is injected into the exhaust of diesel vehicles which significantly reduces the level of nitrous oxide released into the atmosphere. With the UK’s aim to become carbon neutral by 2050, and the European emissions limits becoming increasingly stringent, more vehicles are using AdBlue® to reduce their emissions.

What are the benefits of on-site AdBlue® storage tanks?

AdBlue® storage tanks are commonly used by businesses that use fleets of diesel vehicles as an integral part of their operations. An example of this is companies in the transport industry who required onsite AdBlue® storage to fill up HGVs and LCVs while avoiding forecourt queues and prices. However, with each new iteration of the emissions standards become more stringent, industries such as construction and agriculture are using SCR technology.

Reducing the cost of AdBlue

As well as the convenience of having forecourt style dispensing on your yard, there are numerous financial benefits to having a tank onsite. Prices for AdBlue can vary wildly and purchasing AdBlue in bulk can offer fleet operators real savings even when upgrading from IBCs. Our recent case study shows how upgrading from an IBC to a 2,500 litre tank can reduce the cost of AdBlue to the extent where the savings can pay for the tank within a year or two.

Avoiding AdBlue shortages

We recently reported on soaring AdBlue prices and shortages in some areas due to supply issues with urea, the active ingredient in AdBlue. This led to an influx of businesses purchasing AdBlue tanks as a precautionary measure to reduce reliance on forecourts.

Clean dispensing

Storing AdBlue® in a suitable container is critical as AdBlue® degrades considerably faster when stored in sub-optimal conditions. GreenChem, one of Europe’s largest AdBlue® producers, state the importance of appropriate AdBlue® storage “Storing it in the wrong equipment may result in costly damage to your vehicle due to contamination, which can result in SCR-catalyst replacement and downtime.”

As well as helping to keep the solution clean, AdBlue tanks are integrally fitted with dispensing equipment sited within the tank’s bund. This makes filling vehicles quick and clean with dedicated dispensing equipment.

What AdBlue® storage tanks are available?

We manufacture a range of polyethylene AdBlue® storage tanks in capacities from 1,350 to 15,000 litres. Our AdBlue tanks are bunded and available with dispensing equipment fitted within a lid or cabinet, or as simple holding tanks.

Small AdBlue® tanks

Our 1350 litre adblue tanks and 2500 litre adblue tanks are ideal for sites with a fleet of LCVs, transport companies operating a smaller number of HGVS, and most farms. These tanks come with a lockable flip-lid safely housing reliable equipment including an external pump (230v as standard but with an option of 12v/24v charge), gauge and a nozzle with an integrated digital flowmeter.

Large AdBlue® tanks

Our large AdBlue® tanks are available in capacities from 3,500 to 15,000 litres and are typically used by transport companies with a large fleet of HGVs. These tanks come with a lockable cabinet housing a 230V FMS contents gauge & tank alarm, digital flowmeter, automatic shut off nozzle, 6m of delivery hose and a key switch as standard. Optional extras include a K44 pulsed output flowmeter, 8m self-retracting hose reel and fuel management system. Our large tanks come with a submersible pump.

AdBlue® holding tanks

As well as tanks with integral dispensing equipment, we also manufacture bare AdBlue holding tanks. These are used for sites with existing dispensing equipment or for static machinery requiring bulk AdBlue storage.

buyer

guides

Find out everything you need to know about tanks with our expert guides.

total

satisfaction

96% of our customers would recommend us

What AdBlue® consumption can I expect?

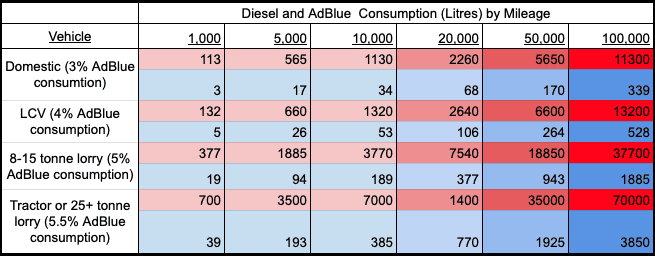

Typically AdBlue® consumption is around 2-6% of fuel consumption. This means that your vehicle will use between 2 and 6 litres of AdBlue® for every 100 litres of fuel. The exact amount depends upon a variety of factors including the type of vehicle.

The table below shows the average AdBlue® consumption depending upon the type of vehicle and mileage. This figure can be multiplied by the number of vehicles in a fleet.

Here, red squares show diesel consumption and blue squares show comparative AdBlue consumption.

What are the AdBlue® storage regulations?

AdBlue® solution is corrosive to some materials and is very polluting to surface and groundwater. Despite this, there are currently no enforced AdBlue® storage regulations in the UK. However, the Environmental Agency has issued storage guidelines and under the Anti-Pollution Works Regulations, they can issue a notice enforcing appropriate improvements.

The Environmental Agency guidelines state:

1. your container, pipework and dispenser equipment are suitable for use with urea

2. you have secondary containment for the container and ancillary equipment (i.e. a bunded tank)

3. the dispensing area drainage is isolated from surface water drains

4. you have a trigger nozzle with an auto shutoff to dispense AdBlue®

5. you have appropriate emergency equipment to deal with large and small spills. Tuffa spill kits are available with your tank

6. you have an emergency plan and suitable training for dealing with spillages or other accidents

Additionally, the Environment Agency, SEPA and the APEA all encourage the use of a Secondary Containment (bund) when bulk storing AdBlue®

How should I store AdBlue®?

AdBlue® stored incorrectly can become contaminated and cause damage to vehicles or equipment. When storing AdBlue® in bulk it should be kept in an AdBlue® tank made from non-corrosive materials such as polyethylene. AdBlue® stored outside should be kept out of direct sunlight in a sealed clean container such as a Tuffa AdBlue® storage tank. Keeping AdBlue® out of direct sunlight and between -6°C and 25°C will prevent contamination and increase the lifespan. All of our AdBlue® tanks are bunded and manufactured from an opaque UV stabilised polyethylene. This means our tanks can be stored outside while keeping the solution out of direct sunlight.

For more information on how to store AdBlue you can check out GreenChem’s Storage of AdBlue video.

What happens if AdBlue® freezes?

The freezing temperature of AdBlue® is -11°C although it doesn’t begin to freeze until -10°C. This means that AdBlue® freezing isn’t often a problem in the UK. However, even if AdBlue® does freeze it can be thawed without compromising the quality of the solution.

How long does AdBlue® last?

When kept in optimum condition (in a sealed container kept between -6°C and 25°C) AdBlue® can be stored for between 12 and 18 months. If stored in a vented container or above 25°C then the shelf-life may be around 6 months.

Do I need a risk assessment for storing AdBlue?

Although diesel exhaust fluid is not classed as a hazardous material it is corrosive to some metals, can cause skin irritation if not handled with care and can harm local wildlife and ecosystems. As such, it is important to carry out a simple risk assessment to identify the level of risk posed and control measures. For help with creating your risk assessment check out our article What to include in an Adblue risk assessment.

How do I maintain my AdBlue® tank?

Our AdBlue® tanks are self-contained storage systems fitted with premium ancillary equipment. As such, maintenance requirements are minimal. However, it’s recommended that you check your diesel tank on a monthly basis and after any episodes of extreme weather. Some of the visible signs you should look for on the tank include:

• The fill point arrangement for soundness and leaks

• Any outlet valves should be checked for leaks and operation (open and close successfully)

• The testing of contents gauge, any high level / overfill alarm and bund alarm.

• If vents can be seen that they are clear and unblocked and free of debris.

• A visual inspection around the tank with emphasis on the base of the tank. The inspection for plastic tanks should include any deformation of the surface of the tank such as:

– Excessive bulging

– Change in colour due to chemical attack

– Crazing or stress fractures.

Is there a future for AdBlue®?

With the UK’s target of emitting virtually zero carbon by 2050, and the subsequent ban on selling petrol and diesel cars by 2030 (or hybrid cars by 2035), is there still a future for AdBlue®?

In advance of the petrol/diesel car ban, electric car manufacturers are refining the high-tech traction battery technology used to power the cars, making them drive for longer between charges and charge more rapidly. Similarly, vehicle manufactures are designing cars and HGVs fuelled by hydrogen. However, in most cases the infrastructure is not yet capable of making these available for mass-market and the percentage of ultra-low emission vehicles within the UK is still in single digits.

As such, AdBlue® and SCR technology remain the most popular and viable way of achieving Euro emission standards. With emission legislations become more demanding it is likely that SCR technology and AdBlue® usage will become much more popular long before it declines. It must also be noted that it is only the sale of cars powered by fossil fuels (including hybrids) which will be banned by 2035 or before. AdBlue® usage for cars will wane thereafter but will still be required until a total ban driving these cars is enforced. Due to the increased difficultly in powering heavy vehicles, the sale of new diesel HGVs won’t be banned until 2040.

While there may not be a long-term future for AdBlue® past 2050, for the meantime it’s here to stay and demands for AdBlue® and AdBlue® storage tanks are only expected to boom this decade.

We hope that you found this guide useful but if you still require further advice or a quotation please submit an enquiry or give us a call on 01889 567700.